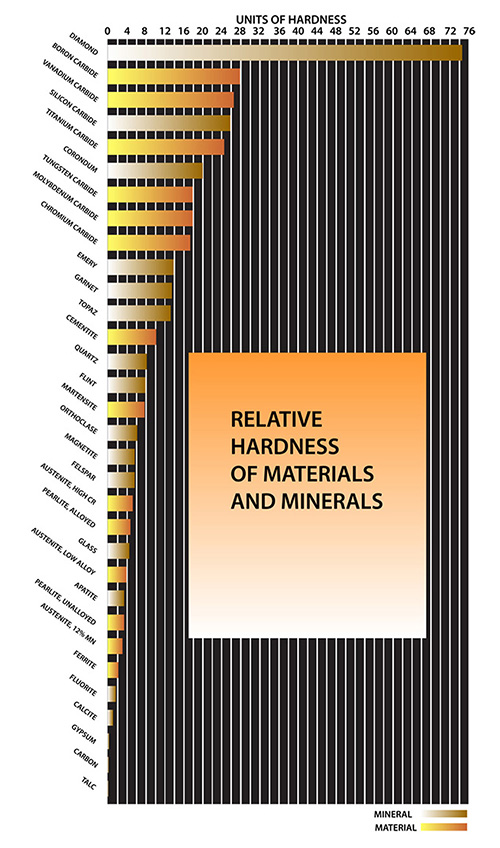

Hukama kuoma kwezvinhu uye Minerals

-

- 1. Dhaimondi

- 2. Boron carbide

- 3. Vanadium carbide

- 4. Silicon carbide

- 5. Titanium carbide

- 6. Corundum

- 7. Tungsten carbide

- 8. Molybdenum carbide

- 9. Chromium carbide

- 10.Emery

- 11. Garnet

- 12. Topazi

- 13. Cementite

- 14. Quartz

- 15. Flint

- 16. Martensite

- 17. Orthoclase

- 18. Magnetite

- 19. Felspar

- 20. Austenite, High CR

- 21. Pearlite, Alloyed

- 22. Girazi

- 23. Austenite, Low alloy

- 24. Apatite

- 25. Pearlite, Unalloyed

- 26. Austenite, 12% Mn

- 27. Ferrite

- 28. Fluorite

- 29. Calcite

- 30. Gypsum

- 31. Kabhoni

- 32. Talc

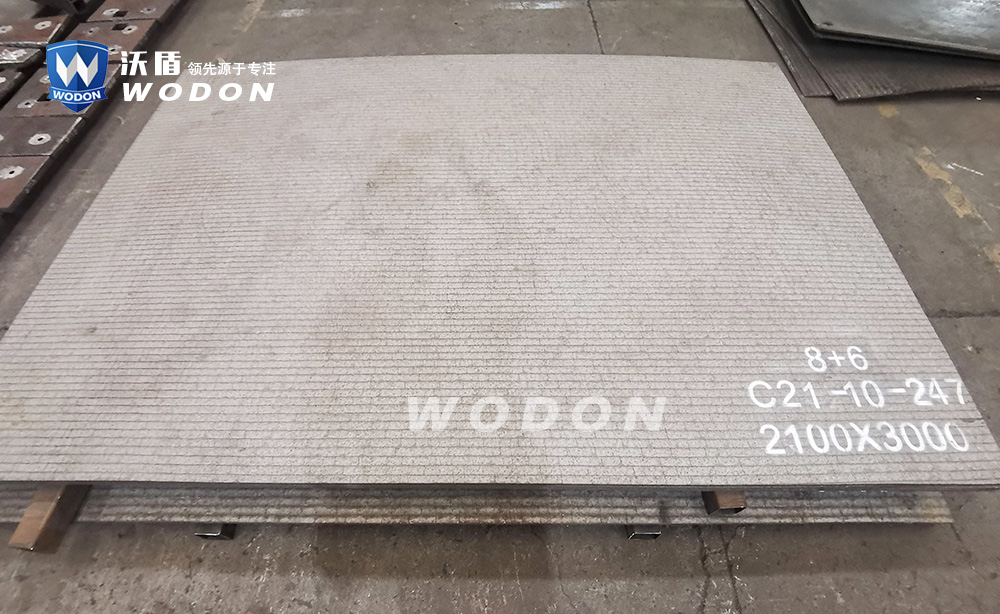

- Wodon vane hunyanzvi mukugadzira Chromium carbide overlay kupfeka plate, isu tinotora yakanyura arc welding technoloy ine yakawanda Cr zvemukati kubva pa25% kusvika 45%. chikamu che carbide volume pane microstructure chiri pamusoro pe50% uye kuoma kwepamusoro kwechidimbu chakaoma iHV1800. iyo ASTM-G65 nzira A iri pasi pe0.16g.

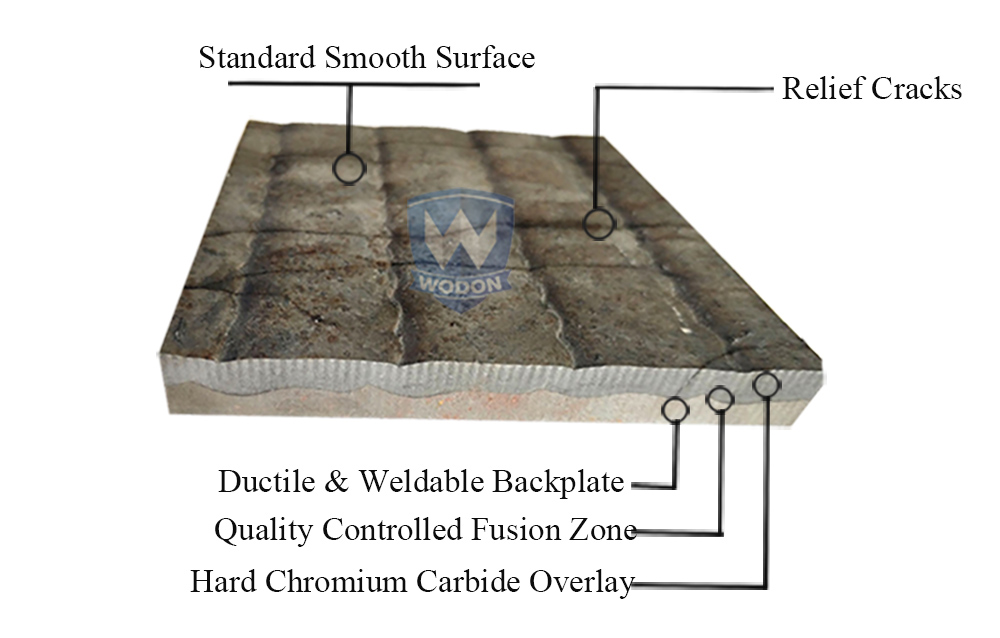

- Chromium Carbide bimetallic ndiro:

- Pakati/Low kabhoni simbi +Abrasion resistant layers →Chromium carbide bimetallic ndiro ine metallurgical bonding

- (Q235/Q345B + Chromium Carbide overlay →Chromium carbide bimetallic plate ne Submerged arc kana Open arc welding

- tekinoroji)

- Tsanangudzo:

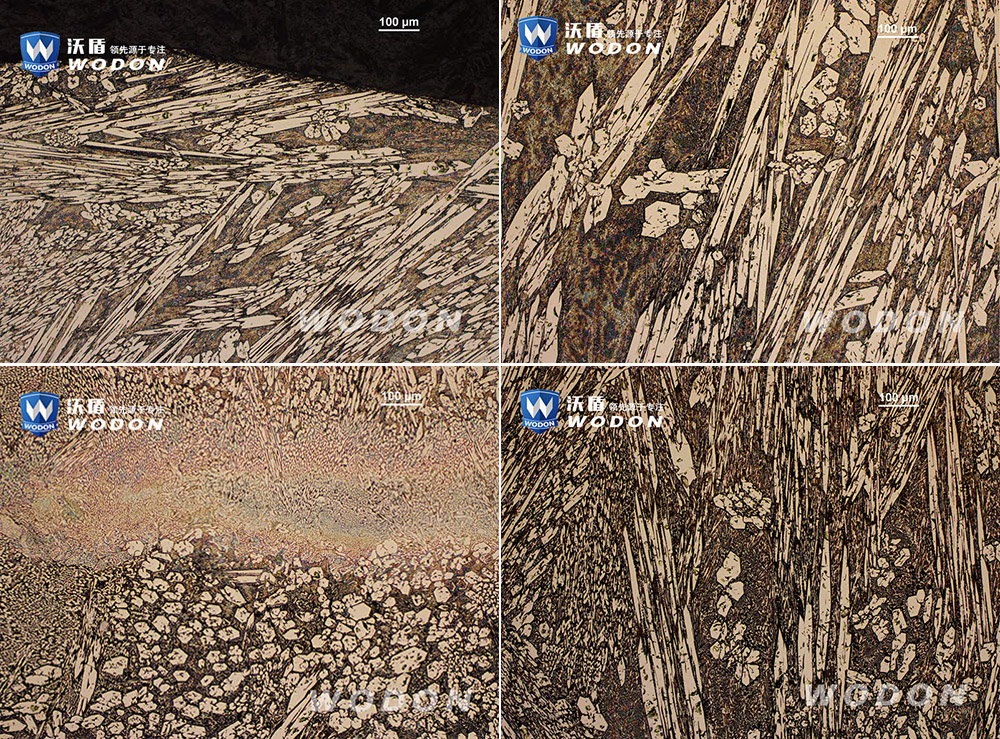

- Iyo yekupfeka inodzivirira layer ine yakakwira huwandu hwechromium carbide yakaoma zvimedu. Izvi zvimedu zvinogovaniswa zvakaenzana mukati mesero, zvichigadzira yakasimba microstructure. Iko kuoma ndeye HRC 58~65uye zvinoenderana nehukuru hwepamusoro.

- Izvo zvakakosha zveWodon ndiro C (%): 3.0 ~6.0 uye Cr(%): 25~45. Ichi chikamu chemakemikari chinoguma nehuwandu hweCr7C3 chrome carbide yakaoma particles. Iyo micro-kuomarara (kusvika kuHV1800) yezvimedu mukati mesero inovimbisa yepamusoro kupfeka inodzivirira pamusoro.

- Iyo yakafukidzira uye base plate ndeye metallurgical bonding. Iyo yakafukidzirwa ichapinda mu baseplate ingangoita 0.8 ~ 1.8 mm, inosvika ku350 Mpa mubvunzo dzedu.

-

- WD1200 kupfeka ndiroinogona kushandiswa kune yakanyanya abrasion applications.

- * Chromium carbide overlay kupfeka inodzivirira ndiro

- * Ne yakadzika arc welding tekinoroji

- * Mushonga weKemikari: C: 3.0-6.0% Cr: 25-45%

- * Chromium carbide Cr7C3 vhoriyamu chikamu chinenge 50%

- * Ukobvu hwekupfeka kusamira layer hunogona kusvika kusvika 50 mm

- * Kudzivirira kupisa kusvika ku600 ° C

- * Lager yakajairwa kupfeka inodzivirira nzvimbo 1400 * 3000mm, 1400 * 3500mm, 2100 * 3500mm

- * Zvirinani flatness ine yakatsetseka pamusoro

- * Kuoma: HRC58-65(650-720HV)

- Aya mahwendefa anoshandiswa zvakanyanya muMigodhi, Simende, Simba, Marasha, Port, Wind turbines uye Metallurgical industry..

-

Nguva yekutumira: Sep-27-2021